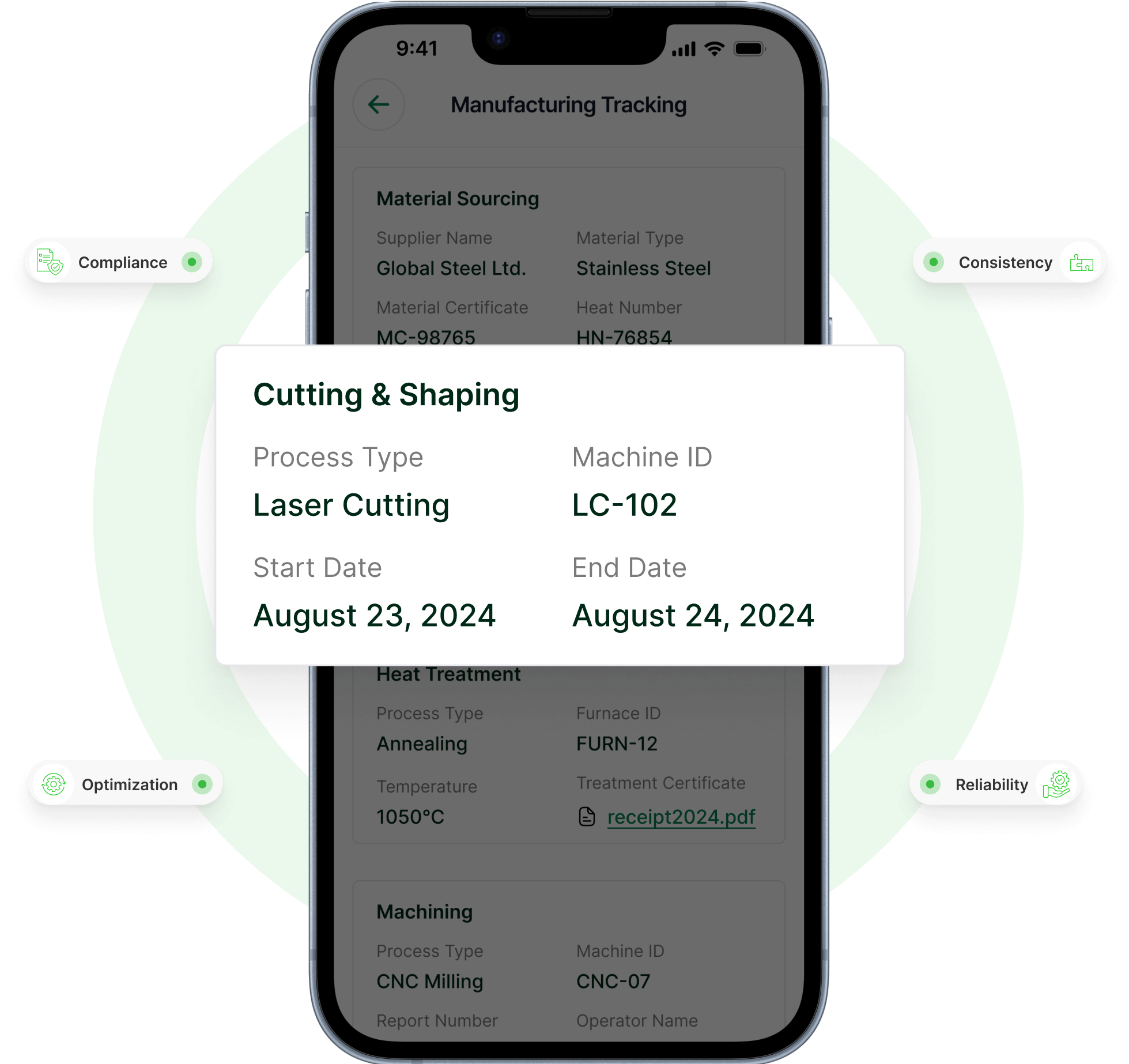

Traceability Software for Manufacturing

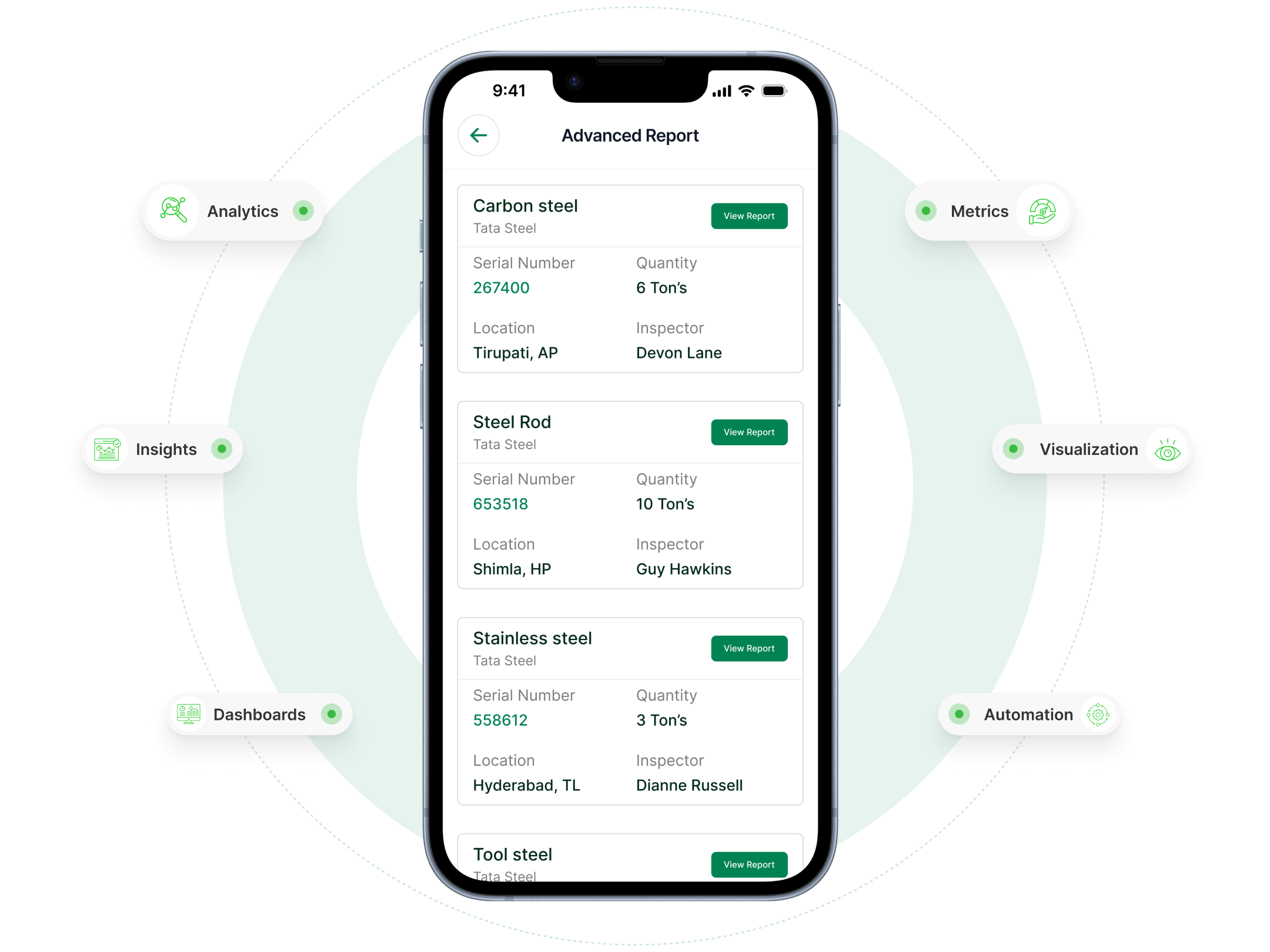

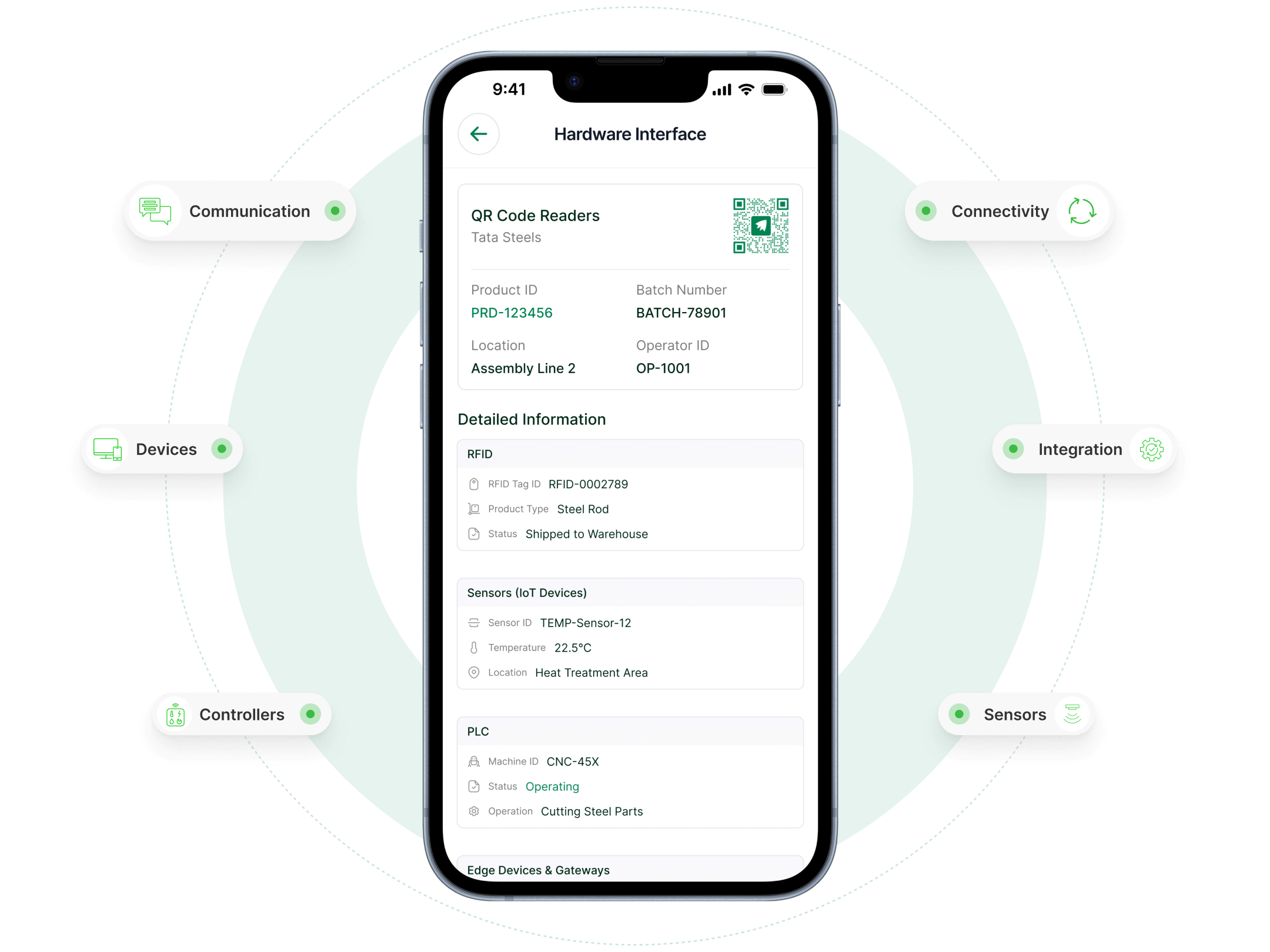

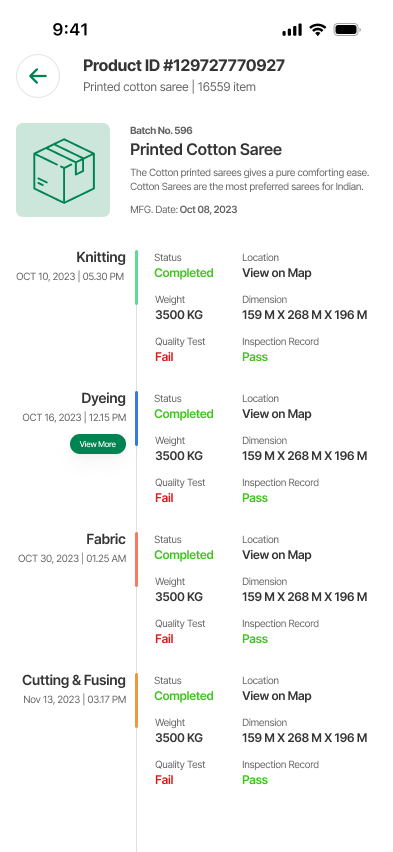

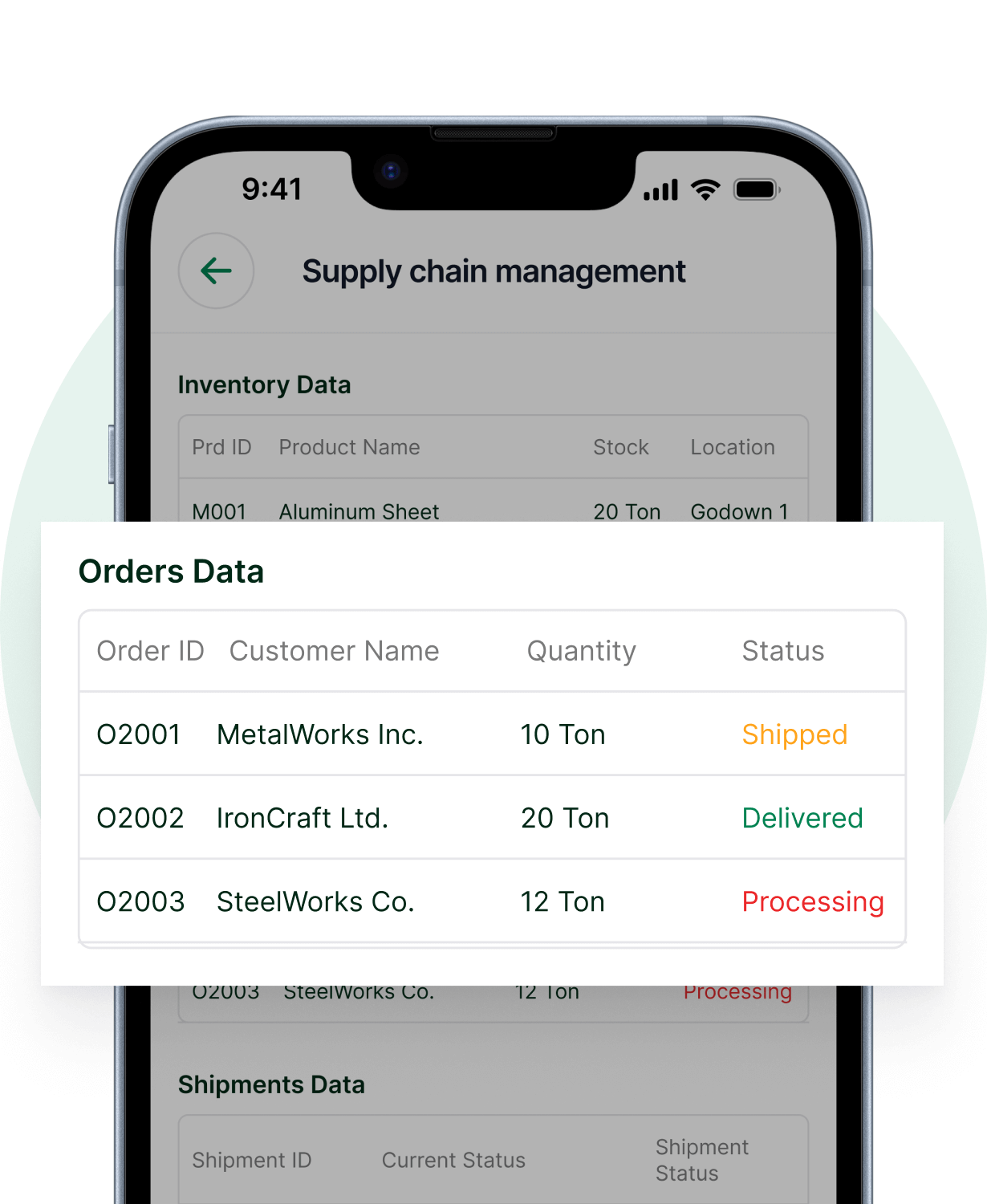

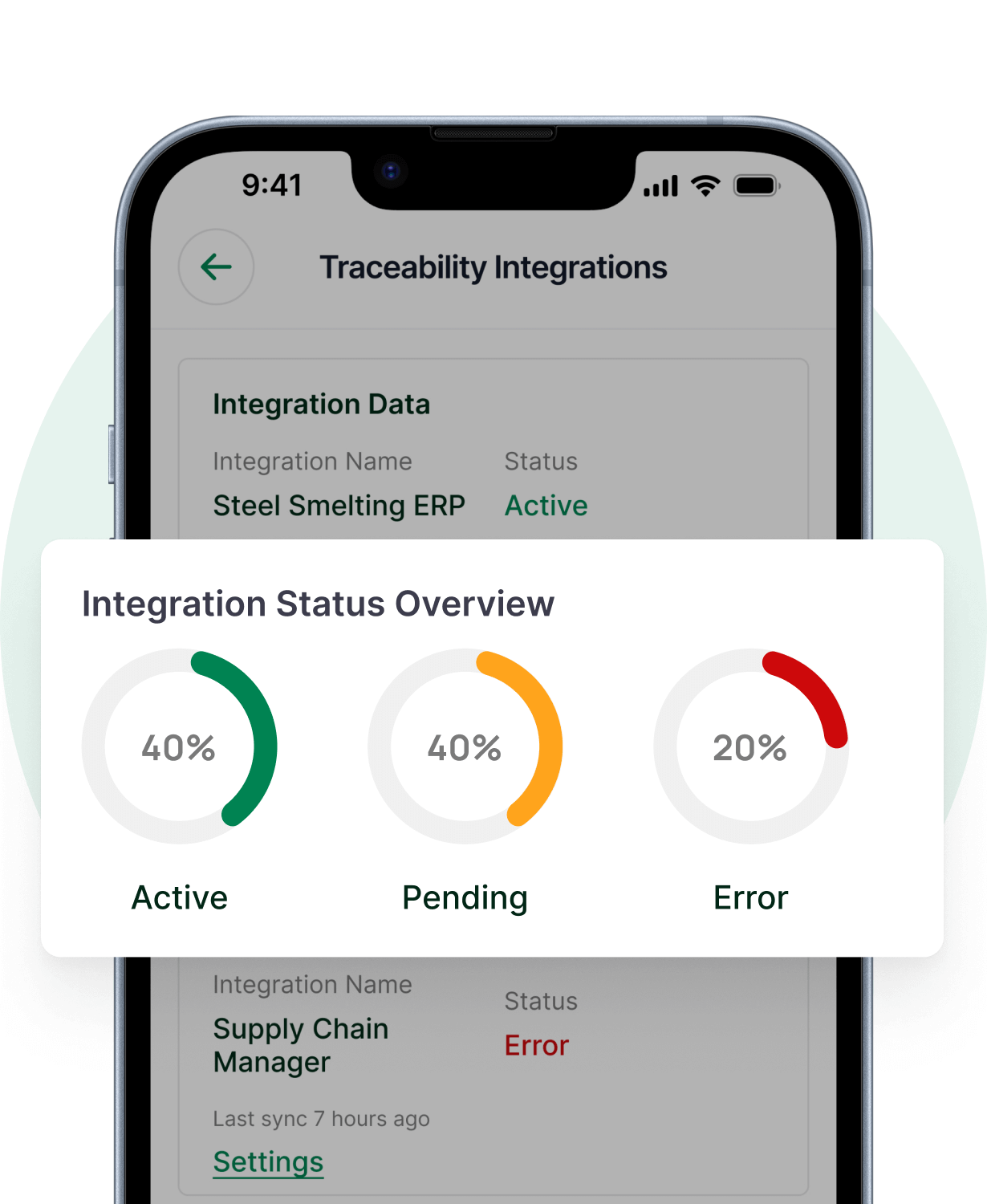

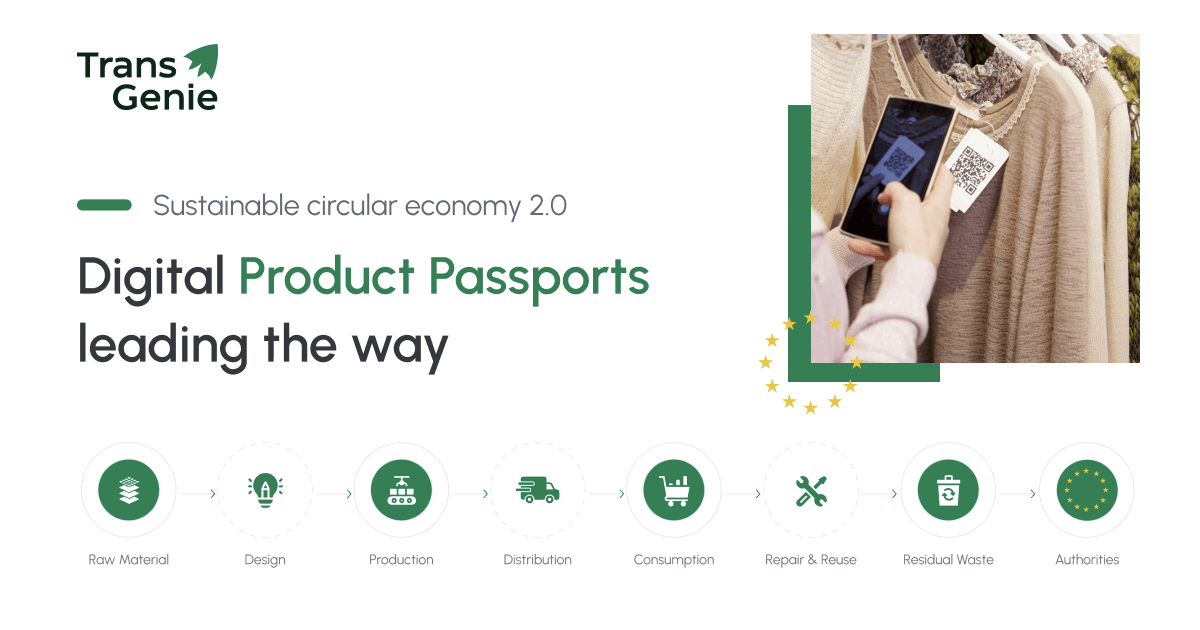

With manufacturing traceability software—easily trace any part or item from raw material to the finished product for better quality management & to meet regulatory standards.

-

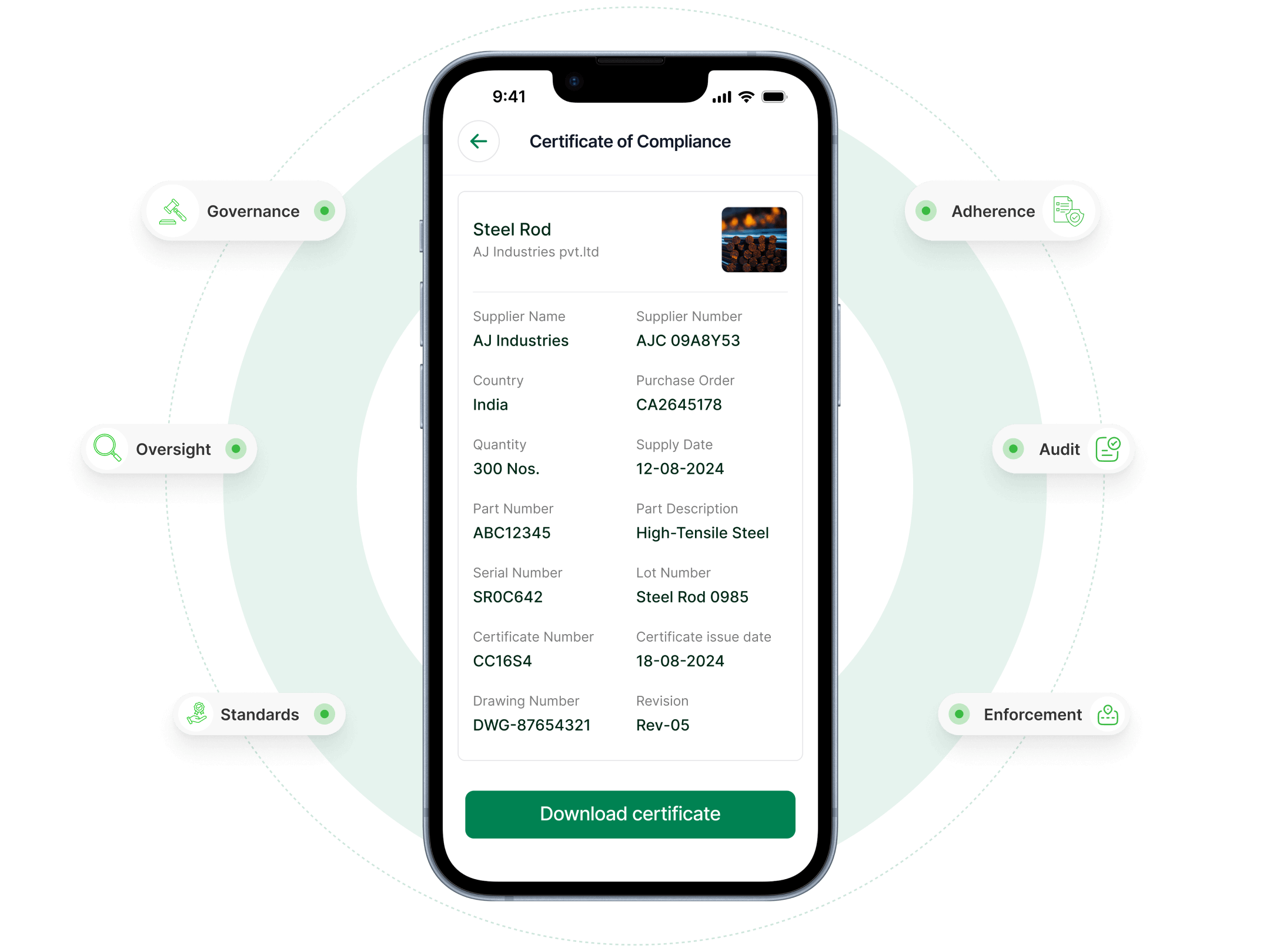

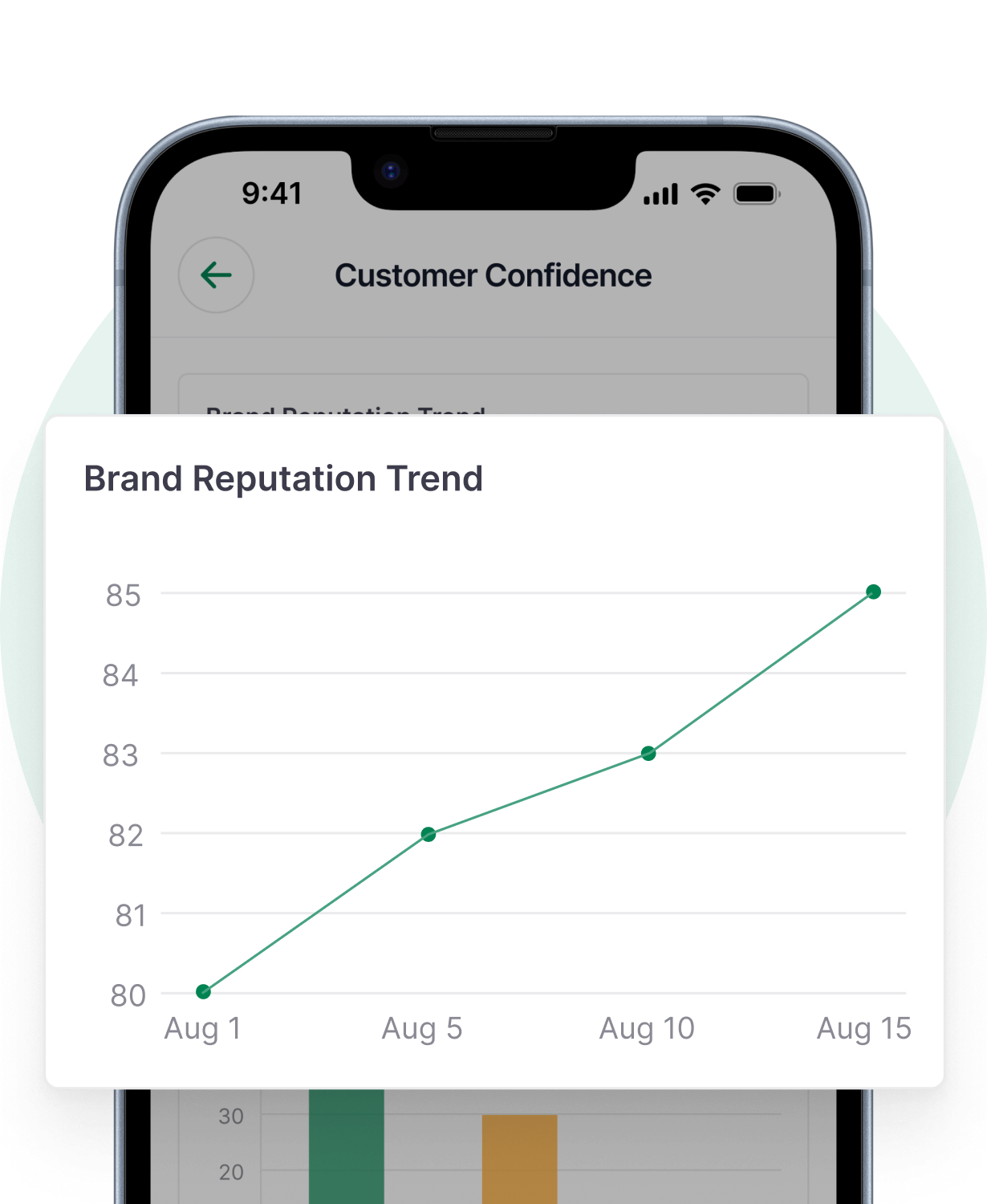

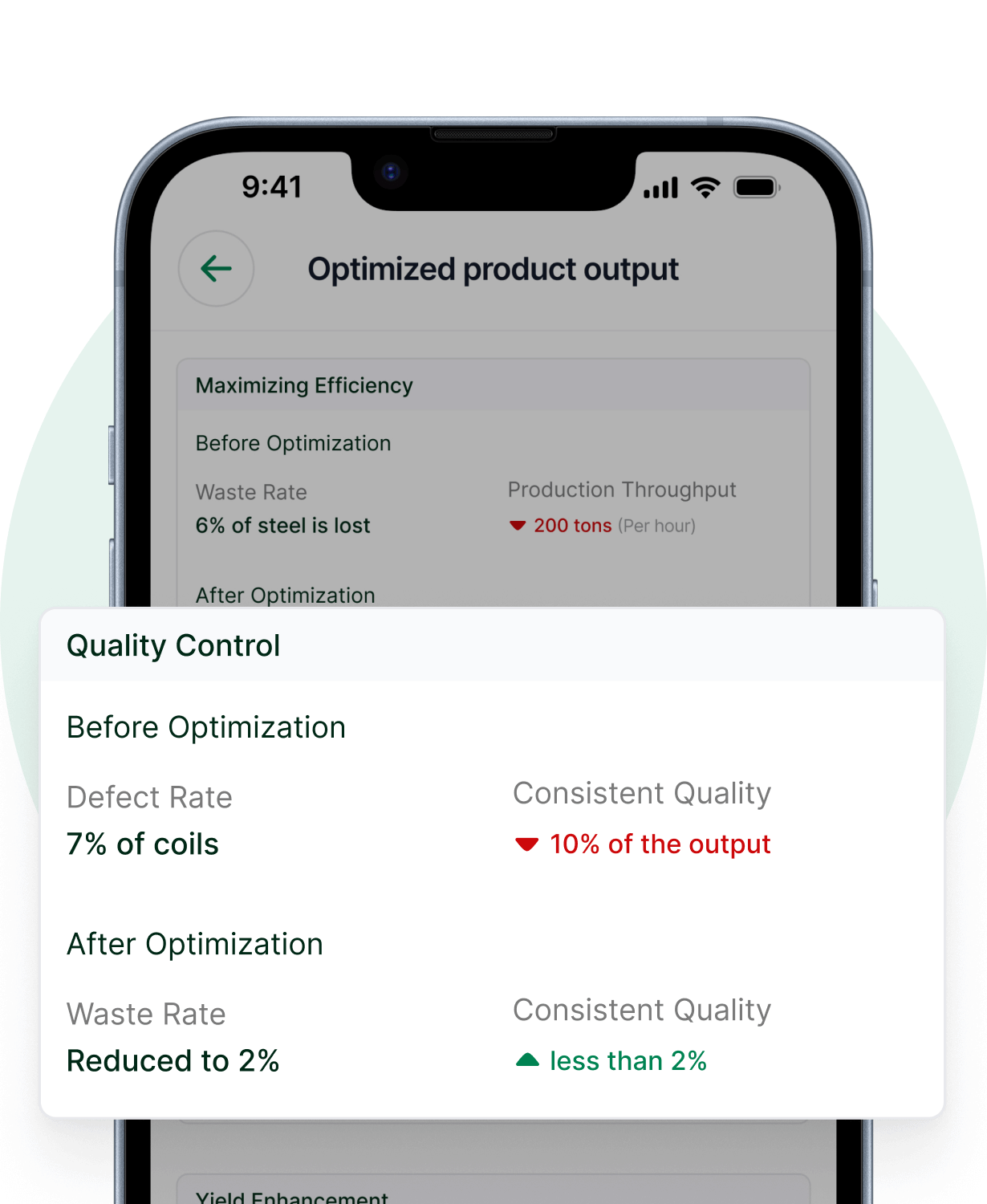

Guarantee the quality of the goods and adhere to compliance

-

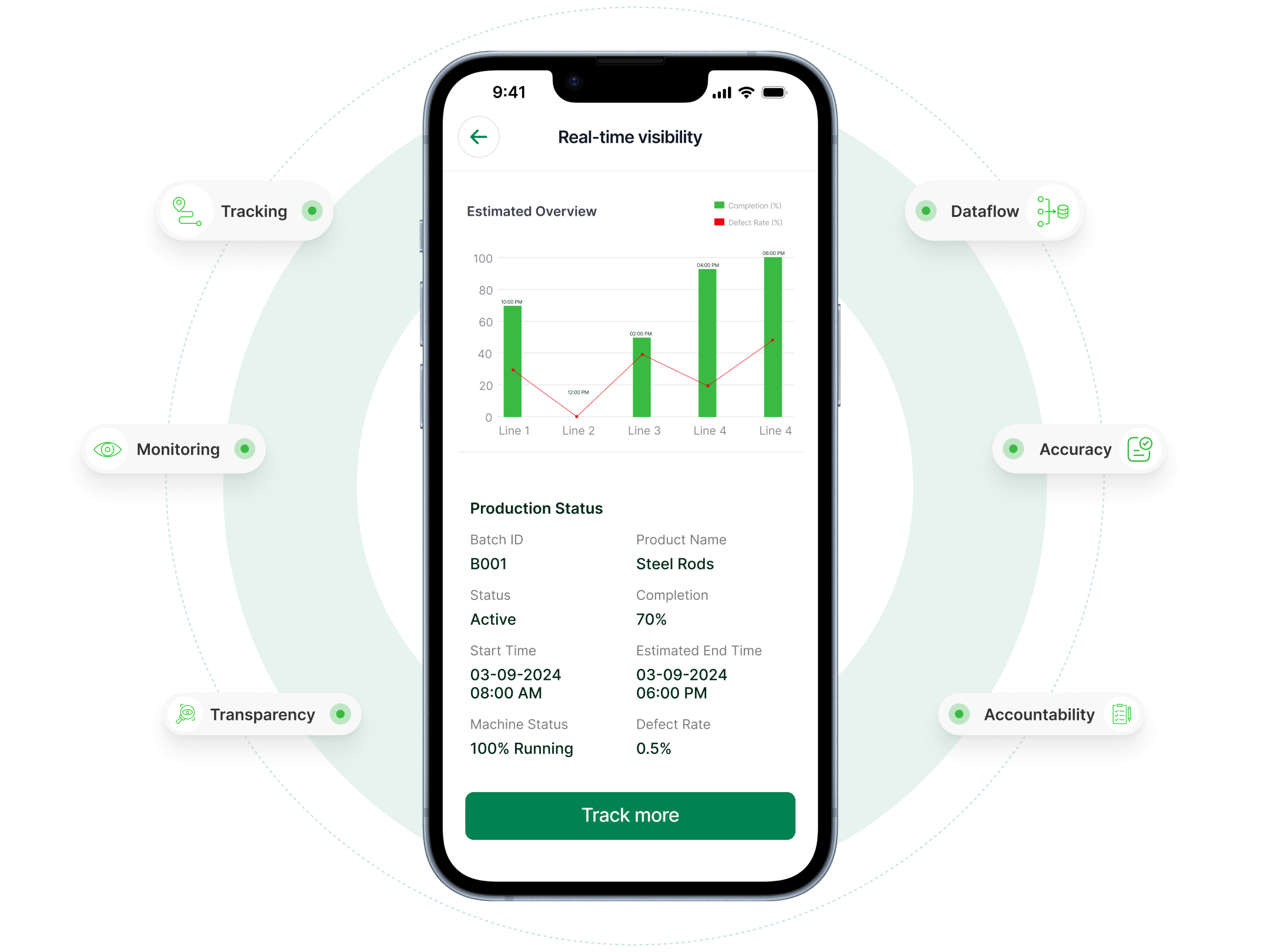

Track and monitor your manufacturing processes in real-time